Surfaces of the external walls

The finish of the external walls is one of the most significant elements of a piece of architecture. In addition to protecting the structure's framework, it contributes to the definition of the distinctive character of a building through its textures, its rhythms, and its colors. Several projects that are carried out on religious buildings implicate the external envelope. In the following chapters, we will look at the various types of exterior that one can frequently encounter in places of worship throughout the province of Quebec.

Surface treatment of the masonry

Stone is well-known for its great resistance and is possessive of undeniable aesthetic and functional qualities. The type of stone that is used, and its various sizes and surface finishes give distinct characteristics to each building.

When properly completed and maintained, a building constructed of stone can last for centuries. This is why it is so important always to carry out the necessary repairs. The problems that occur in the various buildings often point to a lack of maintenance, such as pointing, are associated with the encroachment of water or else structural problems, all of which can cause a crumbling of the stones.

Church of Saint-Michel de Percé

Region: Gaspésie - Îles-de-la-Madeleine

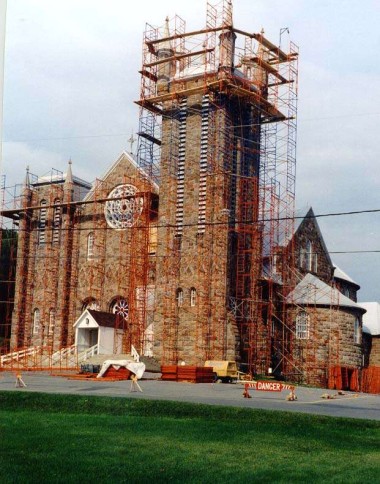

The church of Saint-Michel is located within the heart of the village of Percé, and is considered one of the major architectural monuments of this area. It was classified as historical monument in 1973 by the ministère de la Culture, des Communications et de la Condition féminine du Québec. Built between 1900 and 1912 according to plans by the architect Joseph Venne, the church of Saint-Michel de Percé is a successful blend of Byzantine and Romanesque styles.

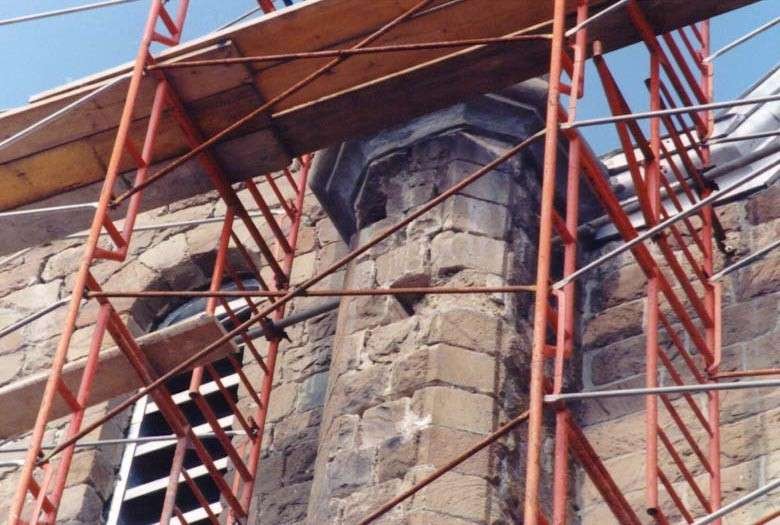

Restoration is aimed at correcting the problems of deterioration of the stones of the façade and the bell-towers. This deterioration is due on one hand to the age of the building, and on the other to its geographical location, with its bad weather and saline air. The stones used for the exterior of the church, are very porous and more inclined to absorb the ambient moisture. This, together with seasonal stress associated with freezing and unfreezing, can cause the stones to burst.

Most of the restoration of the masonry concentrated on the most damaged portions of the façade, the bell-towers, and spires. Following an examination, those stones that were only slightly damaged were stabilized by injection whereas those that were most damaged were replaced. Workers then selected stones on the beaches around the church, to be able to use stones of the identical type. The stone blocks were brought to the construction site, where they were cut to size, squared, then finished, and put in place. With this method, the workmen could be certain to obtain a stone, which was compatible.

Wood lining

Wood is the most common traditional material to cover surfaces. It is at the same time durable, strong, light, and easy to handle. Even though it may be vulnerable to deterioration caused by water, the sun, and moisture, an external covering made of wood that is well chosen, well assembled, and carefully maintained through proper cleaning and painting, can last for centuries. Today, extensive knowledge concerning the properties of this material makes it possible to benefit to the fullest extent from its inherent qualities.

One can find a variety of wood finishes: juxtaposed vertical boards, tongue and groove boards, boards with splice plates, shingles, boards with covering joints, boards with rabbet. Each one of these surface finishes gives an intrinsic style to a building.

The most common deterioration is due to a lack of regular maintenance, which can cause rotting of the wood fibers.

Huntingville Universalist Church

Region : Estrie

The Universalist church of Huntingville is a building of exceptional importance. It is one of the last 'meeting houses' in Quebec that is made of wood. Built in 1844 by the brothers William and Seth Hunting, the church is entirely made of wood. This small church, built in a neo-classic style, has a rectangular ground plan, and is surmounted by a square bell tower. The double-sided roof is made of pinched sheet metal. Very few modifications have been introduced to the building so that it has remained virtually unchanged since its establishment. The church was classified as historic building by the municipality of Ascot.

A second phase of labors has as its goal the restoration of the external surfaces of the church. Depending on their state of preservation, the decorative elements, such as pilasters, spires, and mouldings, will either be re-used or rebuilt according to the original model.

Church of Saint-Paul, Marbleton

Region: Montérégie

The Reverend Thomas S. Chapman, who was both its architect and its master builder, built the church of Saint-Paul between 1851 and 1854. The church is of a neo-gothic style, and is an interessing example, most notably because its interior walls are entirely covered with a reinforced fabric that dates to the 1850's. The external walls in turn are covered with a skirting of vertical wooden boards with splice plates.

Work first of all consisted of repairing the supporting structure and the foundation of the church. Also, the entrances and the portico were redone, as well as the structure of the floor, which was strengthened. Then, the internal and external parts of the spire of the bell-tower were sealed, and the external surfaces of the roofs were repaired. Lastly, the external covering of the walls was reproduced according to the original model.

Sheet metal covering

Sainte-Clothilde Mission in Kitcisakik, Great Victoria Lake

Region: Abitibi-Témiscamingue

The church of Great Victoria Lake is in a Catholic mission built between 1863 and 1870 by the Oblats fathers. Built during the period that had the greatest fondness for embossed sheet metal, the outside of the church is entirely covered in this material (walls, roof, and bell-tower). This substance, which is closely linked to the era of industrialization, expresses the scientific endeavor of the time to search for construction materials that are at the same time easy to use and inexpensive. Several elements contribute to the particular character of this building. Its geographical situation: the mission is accessible only by boat. Its historical importance: it is one of the few 19th-century mission churches, which is still in use. Finally, its covering made of embossed sheet metal: the church with its metal finish became a reference point for planes that fly over the area.

Initially used for interior facing, embossed sheet metal became popular as a covering material for external surfaces at the beginning of the twentieth century. At the time, the external embossed motifs imitated traditional building materials like brick, embossed stone, but also stucco, tile, and slate.

The restoration work on the mission has necessitated a modern sheet metal manufacture, since the original type is no longer available on the market. A thorough search was conducted throughout Québec to find craftsmen who could produce such embossed sheets. Several American manufacturers have again begun to produce decorative embossed sheet metal, but only for interior use. Certain tin manufacturers in Quebec can produce the metal, but only by using small sheets, which are easier to work with (for the project, sheets of a dimension of 18 X 24 inches were sought).

Two solutions were introduced to solve the problem of the church's sheet metal. Firstly, a resourceful craftsman who knew where to find an old metal press that was sufficiently heavy and robust for stamping the sheets produced the coverings for the walls. A good part of the work had to be carried out by hand in order to obtain a sufficiently deep impression.

A second craftsman, starting with a wooden mould, stamped the sheets for the roof on a press, which reproduced the original model. Here again, one of the difficulties was to obtain an impression that was clean and deep enough. The quality of the imprint, its dimension and its color were the essential elements for the preservation the original characteristics of the sheet metal. One can presume that the original sheets were a product of an industrialized process, because they had such a deep impression.

Lastly, the folding and installing of the sheet metal also brought difficulties with it. A manual folding machine had to be manufactured on the spot. The systems of installation and attachment were executed according to the results of examinations of the original sheets.